How to set up a automatic production line of the LED bulb diffuser.

Setting up a automatic injection blow moulding production line for the LED bulb diffuser is very complex. It will need many auxiliary equipment to work together and set up all the programs collectedly. In nowadays, you don`t need to know how to set up this production line. What you need only is to find a supplier who can provide you a turn-key solution.

Guanxin Plastic Machinery offer more than 30 LED bulb cover`s automatic production lines worldwide up to today. Their solution is mature, efficient and energy saving. According to their customers feedback, they can earn the equipment investment in about one year in China. It is about USD 0.01 cheaper for each polycarbonate led diffuser. It means you can save about $16 per hour. Sure, it will depends on the cost of your local market.

Below are some led bulb making machines for the automatic production line of polycarbonate LED diffuser:

* Injection Blow Molding Machine

* Taking Out Robot

* Injection Blow Mould

* Mold temperature controller (200℃ & 300℃ )

* Material Dryer

* Material Auto Loader

* Air Compressor (High and low pressure)

* Air Filters

* Conveyor

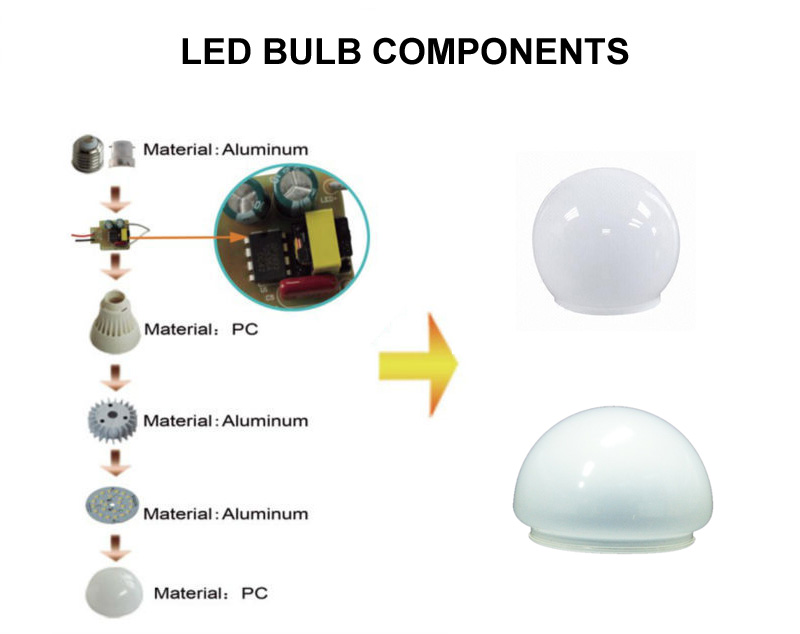

What the raw material of the LED bulb cover?

LED diffusor material is mostly use the modified polycarbonate. This material is good for injection and blow and won`t turn to yellow after long life heating.

What is the cost of led bulb making machine?

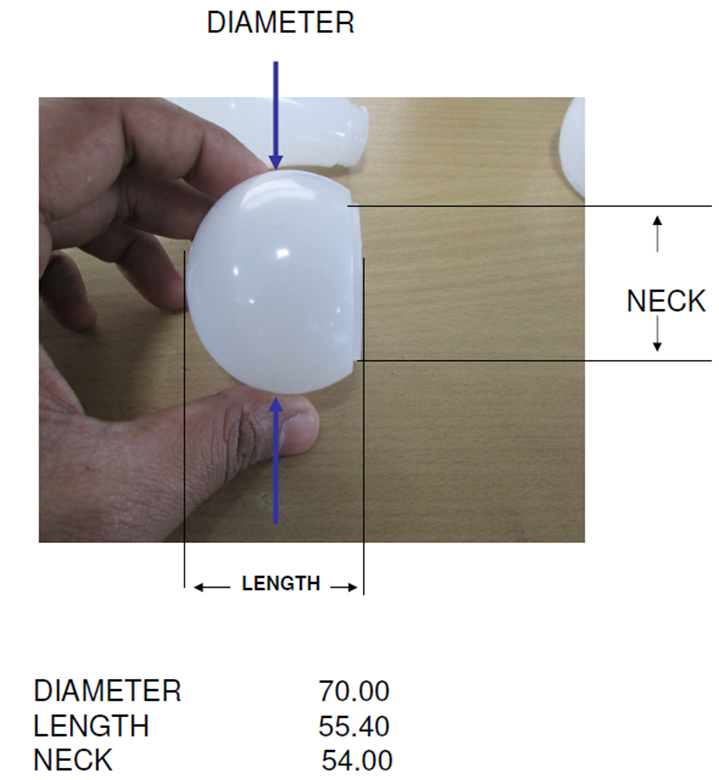

A LED bulb light have many components like the polycarbonate light diffuser, PCB board(Aluminum + LED chips), heat sink(Aluminum inside + PC outside), Light Driver, Socket(PC inside + AL. Base). Every part will need a few machines to build up a automatic production line.

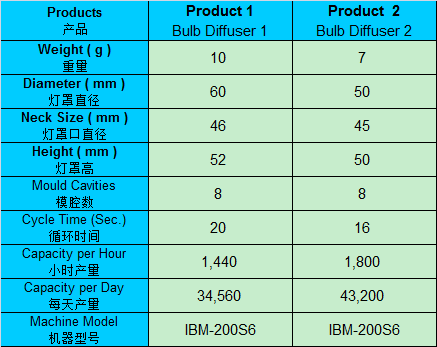

Here we choose the polycarbonate LED diffuser for example to show you the LED bulb manufacturing project cost. Maybe you are confused while the automatic production line for the cover? It`s because it`s light and cheap comparing to other LED bulb parts. It take too much room and shipping cost if you buy it outside.

A Automatic Production Line of Polycarbonate LED diffuser cost about 100,000 USD and contains bellow equipment:

* IBM-200S6 200 ton Injection Blow molding machine with quality servo motor

* Taking out robot

* Air compressor(1.0 m3/3.0 Mpa)+ Air tank

* Hopper dryer (50kgs)

* Mould temperature controller for 200℃ X 3 PCS

* Mould temperature controller for 300℃ X 1 PC

* Air Dryer + Filter

* Full hot runner IBM mould for 8 cavities

Plastic Injection Blow Molding Machine Manufacturer in China